The complete guide to disc brakes on road bikes

David Millar recently raised an interesting point about disc brakes on road bikes, but it's not the whole story.

by Evan McNeely

On April 14, 2015, the UCI issued a statement announcing that they would allow professional road cycling teams to begin testing disc brake-equipped bikes, at two events of their choosing, during August and September. This news came after nearly every major bike manufacturer had introduced a disc brake-equipped bike into its line. The machines were essentially marketed with “have what the pros can’t have.” Since then, a few professional teams have experimented with disc brakes in competition.

Recently, retired professional road racer David Millar took to Twitter on the subject, claiming that the difference in power of hydraulic disc brakes and traditional rim brakes means nothing if the tire is already maxed out, sliding in a skid on the tarmac. Millar raises a very interesting point, but it is not the whole story.

It’s simple, it’s not about braking, it’s about surface traction. A modern caliper vs disc brake means nothing – the tyre is already at max.

— David Millar (@millarmind) November 24, 2015

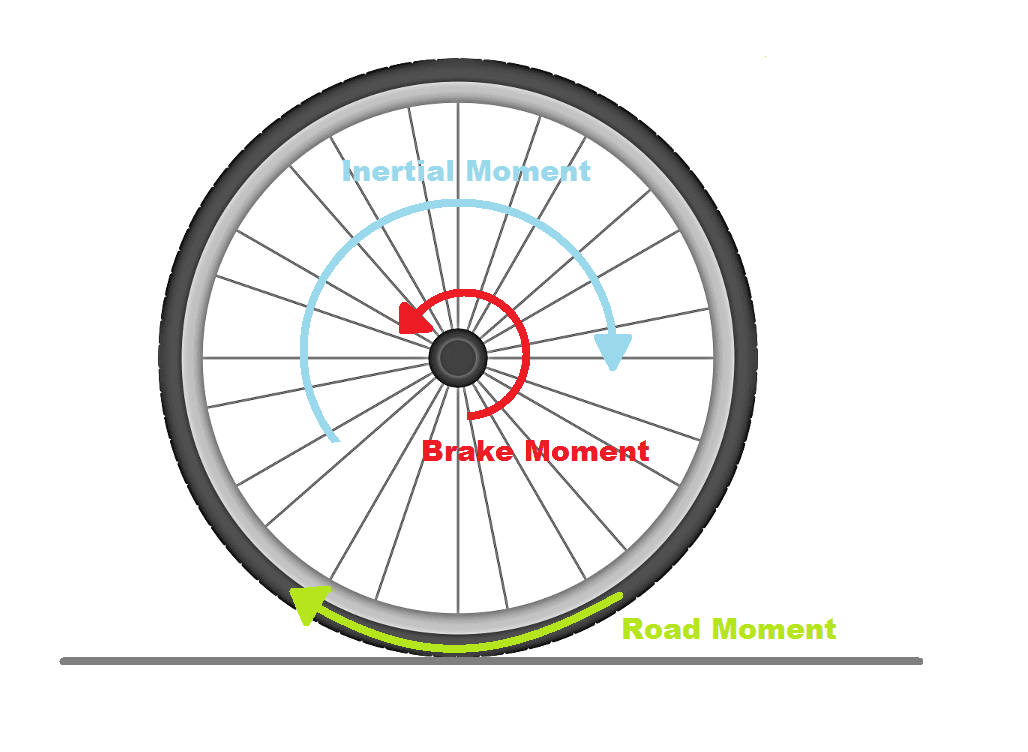

Brakes slow you down by applying a “moment” onto your wheel in the opposite direction that the wheel is spinning. A moment is a fancy engineering term for a force acting around the centre of rotation of a wheel. The road is also applying a moment on the wheel at the point of contact the tire makes with the road’s surface. The wheel also gains a moment of inertia once it starts spinning. The moment of inertia is the wheel’s desire to keep spinning once it has started spinning, and is also known as Newton’s First Law. I will call these moments the braking moment, road moment and inertial moment, respectively. If the braking moment applied to the wheel is greater than the road moment and inertial moment combined, the wheel will lock up and you will enter a skid. In this instance, David Millar is correct in saying that it doesn’t matter whether you’re on disc brakes or rim brakes, the distance that it takes you to stop is only dependent on the friction between the road and tire. However, when bombing down a hill at 80 km/h, the wheel gains a large inertial and road moment. This situation means you can apply a huge braking moment without entering a skid. In this scenario, disc brakes can greatly decrease the distance it takes to come to a complete stop. Traditional rim brakes can’t apply anywhere near the braking moment that a hydraulic disc brake can.

Besides the increased braking power, hydraulic disc brakes allow you to modulate the braking moment you apply to the wheel much more effectively. No more death gripping the brake lever to slow down. With disc brakes, you can apply “just the right amount” of braking, whether that’s a lot or a little, before entering a corner or descent using only your pinky fingers. Performance of disc brakes are also minimally affected by adverse weather conditions. Wet or dry, you can stop quickly and safely. But there are still a few concerns facing the complete adoption of the disc brake.

Some say disc brakes are just “solving a problem that doesn’t exist.” True, rim brakes do not have any problems, but that doesn’t mean they can’t be improved upon. Disc brakes will allow you to brake later coming into corners for increased speed in technical crits and on steep descents. Disc brakes will increase safety on city streets and wet conditions. It’s not about solving a problem, it’s about increasing performance.

While hydraulic disc brakes offer big performance improvements over over traditional rim brakes, there are still several concerns competitive racers and weekend enthusiasts. These concerns include wheel changes, brake overheating, crash safety, disc and thru-axle standards and neutral support.

Wheel Changes

Before discussing wheel changes, I should mention that thru axles should be implemented along with disc brakes. “Brake pull”—when a bike pulls to the left under hard braking—happens on a frame running disc brakes and quick-release skewers. Disc brakes apply a very high force to the left fork blade only, causing the left blade to deform independently from the right one. A thru axles can address this imbalance; it provides a more secure connection between the dropouts and hub.

Thru axles do make wheel changes slower, but not by very much. The thru axle is threaded into the frame for a secure connection. The axle needs to be unthreaded before it can be pulled from the hub, releasing the wheel from the dropouts. However, with new products, such as Rapid Axle Technology, will speed up this process significantly. Slower wheel changes is a problem that thru axles create, but it’s a problem that can be easily solved with a little innovation.

Overheating Brakes

Descending a mountain pass requires a lot of sustained braking. Rotor and brake-pad temperatures will certainly rise above what is usually experienced on cross country mountain bikes, where braking is in short bursts with lots of time for things to cool down. Road disc brakes will need to be designed a little differently than what is currently in use on cross country or downhill mountain bikes. In fact, Shimano has already released road-specific calipers. Trust me when I say that Shimano’s engineers know what heat transfer is and are designing around these road-specific applications.

Difference in Braking Power in the Peloton

During the disc-brake transition period, some of the riders in the peloton may have disc brake-equipped bikes while others will still have rim brake-equipped bikes. As I mentioned, the difference in braking power here is big; some riders will be able to stop much quicker than others. In a group of 100 tightly packed racers, this difference is a significant rider-safety concern.

Matteo Dal-Cin from the Silber Pro Cycling team put it this way: “If some teams switch to disc, but not all teams can afford to or co-ordinate the switch at once, the variability in braking performance would be scary, especially in the rain.” Dal-Cin has already experienced this issue when racing ‘cross this fall. “When I came up on the back wheels of guys riding disc brakes,” he said, “it was always a shock how much later and better they could brake for a corner.”

Chris Reid, manager of the Cyclery-Opus elite women’s team, also had concerns about the difference in braking power in the peloton. “Being a road racer is like being a lemming,” Reid said. “Half the time, you’re barrelling into a corner with the implicit assumption that you can do the same thing as the guy ahead of you, and assume it’s all gonna work out just fine. If he suddenly slows quicker than you’re capable of…well that kind of bends that reality!”

Disc and Axle-Size Standards

Disc brakes and thru axles have been implemented on mountain bikes for several years now with the idea of a “standard size” still looming mysteriously. Thru axle diameters and widths have so many different combinations, you would need a spreadsheet to calculate all the different possible variations. Disc-brake rotor sizes add more uncertainty to the mix. This lack of a standard size poses a big concern for disc brake-equipped road bikes, especially when it comes to neutral wheel support.

There are many situations in which a rider may need neutral support during a race: he or she gets a flat tire and can’t get in contact with their team car, for example. “We receive support from the team car, as well as neutral support from the race organiser,” Dal-Cin said. “Neutral support would seem to be a big problem since everyone would have different size rotors and their calipers in different places on their frames and forks.” It always sucks to see a race decided by mechanical failure. It would be an even bigger shame if neutral support was there but was unable to lend a helping hand.

Evan McNeely is a professional mountain bike and cyclocross racer. He’s also a fourth-year mechanical engineering student at Carleton University.