Chromag keeps it Canadian with new Doctahawk

Ian Ritz, founder of the Whistler company with a reputation for envelope-pushing steel hardtails, talks about the new frame and adding Nanaimo's Brad Howlett as the latest frame builder

When Chromag released the Doctahawk last week, the latest in its line of progressive chromoly hardtails, it sent caused a bit of a stir.

The Whistler company has built its considerable reputation in part on pushing the presumed limits of frame geometry, building hardtail’s to be ridden on some of Canada’s steepest, most challenging trails. But, even compared to Chromag’s already-progressive Rootdown, the Doctahawk stands out. It has a visibly longer reach, an extremely slack HTA and is designed to be paired with a 180mm fork.

While the 62-degree head angle grabbed headlines another, less sensational detail was just as interesting. The new frame will be hand made in Canada by veteran B.C. frame builder Brad Howlett.

I talked to Ian Ritz, founder and owner of Chromag about the new bike, how Chromag connected with Howlett and why it’s important for the brand to continue making frames in Canada and what riders might expect to see rolling out of its headquarters in Function Junction in the future.

Canadian Cycling Magazine: Brad Howlett is the latest frame builder to join Chromag, but the company has always offered hand made frames produced by local Canadian builders. What’s the history of these relationships?

Ian Ritz: Prior to Brad, we worked with Mike Truelove and Chris Dekerf. We started with Mike about 16 years ago, and he was our sole builder for many years. When we started painting our frames at Chris Dekerf’s shop, he showed an interest in doing production as well. At the time I had a really good relationship with Mike, and I didn’t want to take any of his work away, but we happened to be looking at adding a new model, a 29″-er and we decided to develop and produce that with Chris.

So how did you connect with Brad Howlett for the Doctahawk frame?

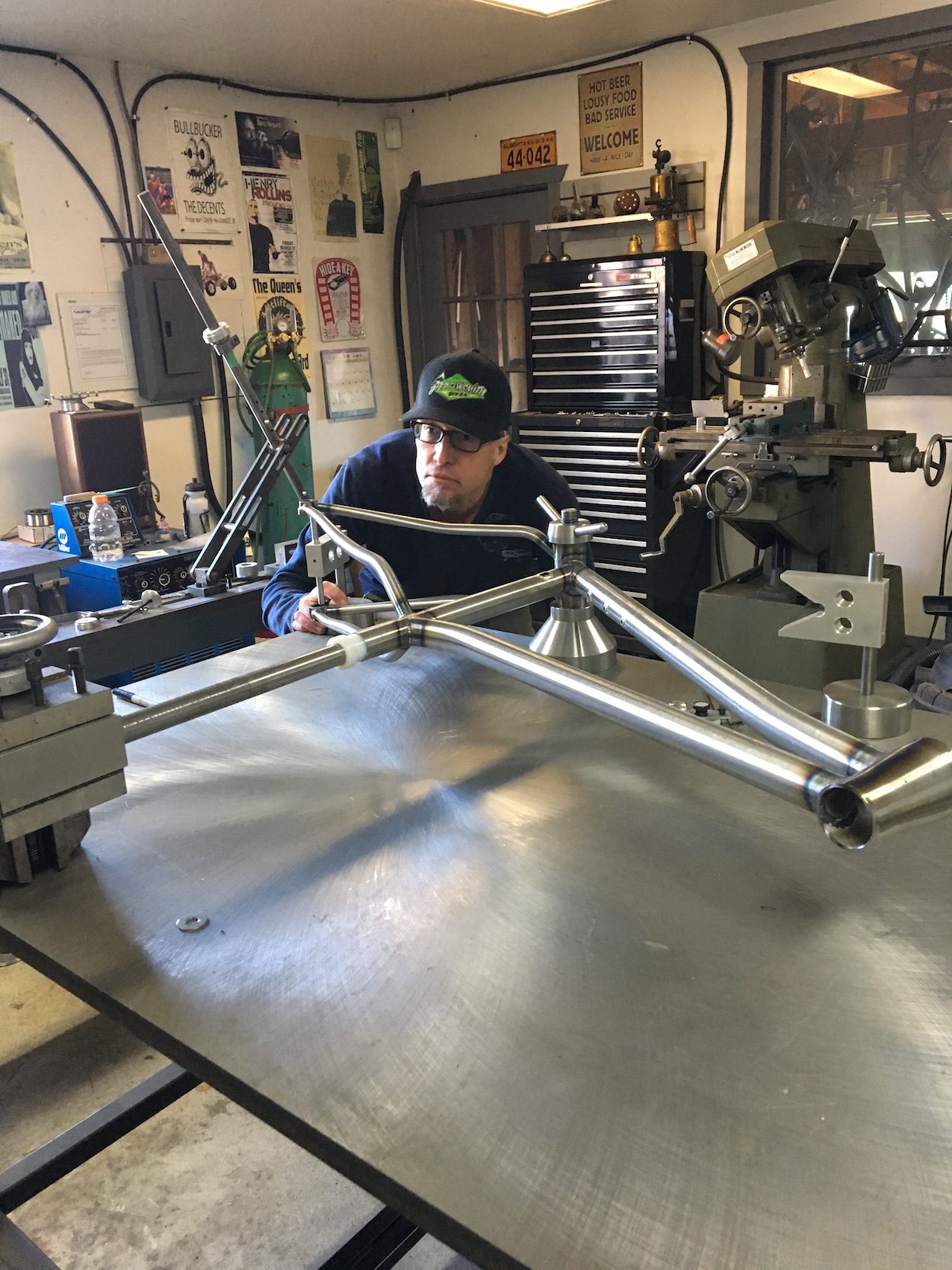

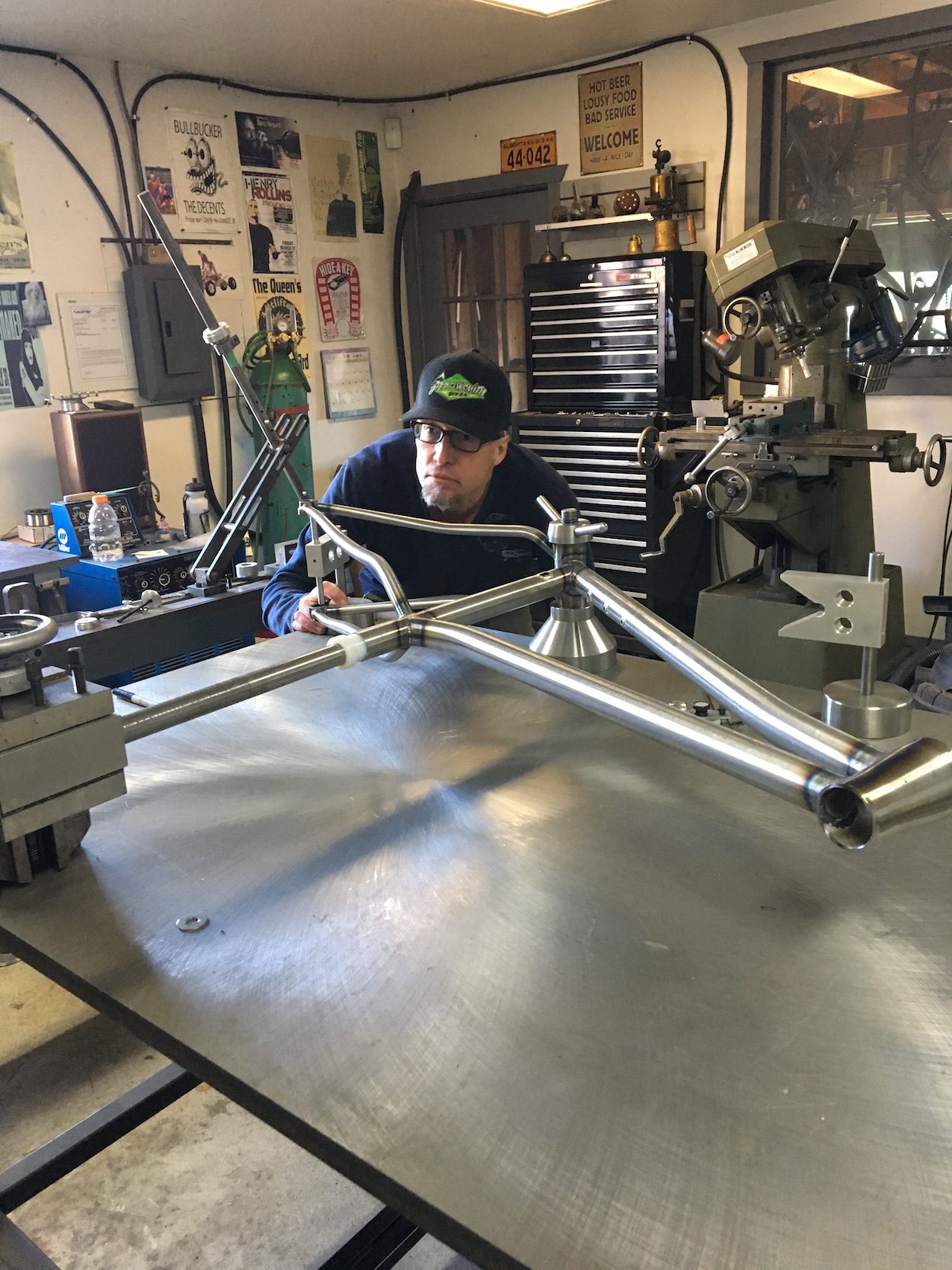

Just over a year ago Chris told me about Brad, who actually had been working with Chris on the last two years of Surface production. Chris is an extremely picky fellow. He’s very demanding to work with and he’s easily one of the best welders in North America. So that was a pretty good recommendation for us to have confidence in. It was around that time that one of our testers was pushing us to try a new geometry so we decided we’d get Brad to make the prototypes for us.

We went forward with this project. The three prototypes we had made, we decided to clear coat them all so we could get a look at his work, and I was super impressed with the job he did. He was also flexible. We had variations in the prototype phase, including different chainstay lengths, which requires him to change up his tooling. He handled it all without complaint.

While Chris Dekerf is well known for bikes he’s built as Dekerf Cycles, Howlett hasn’t gone the route of making a custom bike business of his own. Can you tell us more about his story?

Brad currently lives in Nanaimo, B.C.. In the 90’s he did work for a few bike companies, Rocky Mountain being the most notable. He also worked for Chris Dekerf when Chris had several models and a big production operation going. He also worked for a couple brands on Vancouver Island, PDC Racing was one and also Basic bikes.

In the late 90’s most of that work shifted to Taiwan. Brad ended up getting involved in race car fabrication for the following decade, making drag racers and sand racers. I would imagine that would also be quite a demanding type of fabrication process. So he’s been working in welding and fabrication for somewhere in the neighbourhood 30 years now.

Was Howlett involved in the design process for the Doctahawk? Or did he come onboard after that process was finished?

No. Although something we do ask of our welders, and one of the great features of working with a Canadian welder who is local and rides bikes is that you do get feedback about the fitment, or weld space in the design.

Why is it important for Chromag to continue to offer Canadian made frames in addition to the Tawian made options?

It’s something that our customers value and that they demand. I love the process of working with a Canadian welder because there’s a very close connection between that person and the actual purpose that the bike is being made for. Each of our welders are regionally situated where the bikes are being designed and ridden, so they have a connection to that sport and the environment and an understanding of what the purpose of the design is.

One thing that really differs in the process of a bike that’s made locally is that that bike is made from beginning to end. They do every cut, every hole and ever fitment themselves in welding that bike from beginning to a complete frame. That’s a very different process than what happens in Taiwan. The Taiwan process is very, very good quality, and very efficient. With a team of twenty, you can make one hundred frames in a day or two, whereas with a single welder, like Mike or Chris, you’ll basically make a frame in a day.

Its a very different process. I think what our customers like about buying from a Canadian builder is they know that person has made their bike from end to end, I think there’s this much more personal connection to that end product.”

Clark Lewis, a local Whistler EMT was involved in the Doctahawks design process. How did that come about, and what was his role?

Clark is a really good friend of ours, he’s a riding buddy. He’s big strong guy who really rides hard, so he’s a great product tester for us. He had been bugging me for a while about conjuring up a design that he thought would be more progressive than what we’ve done so far. Which is ironic because we have thought we were very progressive all along as a hardtail brand.

Clark and I sat down at the CAD station together and designed this bike. I did the drafting and he pushed me one way or another to make it to his vision. There were a couple things we were unsure about, so we designed variations into our prototypes and asked Brad to make them.

And it’s Lewis’ nickname that ended up inspiring the name for the new frame?

Yeah, Clark has a reputation for pushing the limits. Maybe you’re familiar with the term Tomahawking in skiing, where you lose everything and you’re going end over end for a long time. So, Clark has a bit of a reputation for that. But it makes him a good tester and he’s definitely a guy who like to push limits. In a way, that’s what this design process was about as well.

The Rootdown, with its 64-deg HTA and 160mm fork, is already pretty progressive. Doctahawk takes that several steps further. How much further do you think you can go? Or does this frame push up against the limit?

Well we keep thinking we’re hitting the limit. Although the Doctahawk did take a bit of getting used to, it could very likely go further. So I can’t say it won’t go further, and you really can’t say unless you continue to prototype and test.

Having spent time on a Rootdown, it is still impressively capable on quite a wide range of terrain. Is this the same for the Doctahawk? Or does its more progressive geometry mean focused on just riding really steep terrain?

You know, I thought this would be the first hardtail we made that wouldn’t be great at climbing, and would just be slated as a descender. But I would say that this bike climbs just as good or better as any of our models do. I was kind of amazed that with the long front-centre, the steep seat tube angle, and just putting the rider on top of a long bike, that it still climb incredibly.

For me, on a personal level, this would be the bike that I would ride gnarly Whistler trails, but the Nimby Fifty is a three hour bike race in May, and I’ll ride this in that too. So I think it’s still very versatile. I think smaller details like what tires you run will make a bigger difference in where you can ride this frame.

[Ed. note – Nimby Fifty is only three hours if you’re going fast. In fact, the race organizers designate any rider finishing under 2:55 for men and 3:15 for women as Platinum Club finishers. Ritz is one of them.]

Chromag has been involved in Nimby Fifty, held just down Hwy 99 in Pemberton, for several years. This is the tenth and last year that race is being held. Would you have any interest in getting a similar event going on Whistler trails?

Ha ha, I don’t know. Running a bike business it’s hard to conjure up the time to run a major event. Certainly there’s been several iconic events around here that we’ve enjoyed. We had a series quite a while ago called the Samurai of Singletrack that ran for seven years, and I’d love to see something like that happen again, for sure.

Before the Doctahawk, the last new Chromag introduced was the Surface Ti. Are there any other titanium frames in the works?

Maybe. We have some new prototypes coming that are not so different from these Doctahawks, to be honest. Whether or not there will be customers that want to buy a $3,600 hardtail with this kind of geometry, we don’t know. But, if nothing else, I think the Surface will probably get a little more aggressive in the next iterations.

Last, a question I’m sure you’ve been asked a few times before. There’s been more steel dual suspension bikes coming out, largely from the U.K. Are there any plans for a dual suspension Chromag?

Well, we have a new engineer, Ben Arnott that’s been with us for a year now and he has a lot of experience in the suspension world. We have been sharing lots of ideas so it’s quite possible we will go down that road eventually.

[Ed. When not in Whistler working for Chromag, Ben Arnott travels the globe as a World Cup mechanic, most recently for the YT Mob]

The Chromag Doctahawk is available now for order online and through your local bike shop.