Revel shows off the Rodeo: a world’s first 3D-printed full-suspension mountain bike

Pushing frame production into new territory

Photo by:

Revel Bikes

Photo by:

Revel Bikes

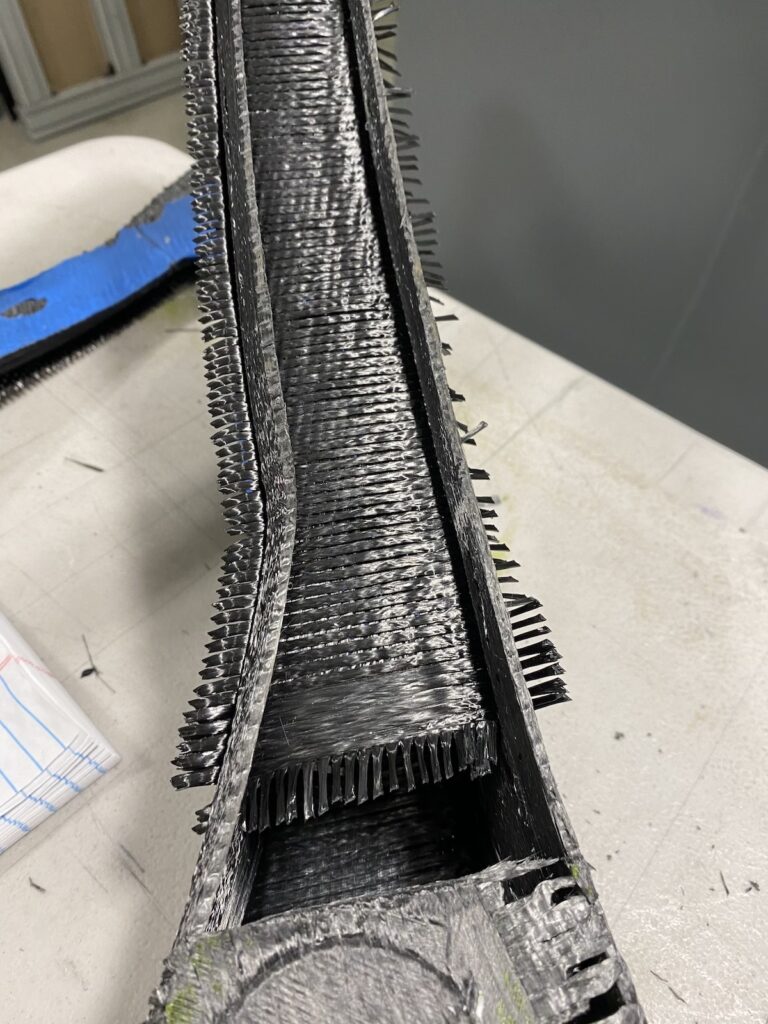

Revel Bikes is showing off the Rodeo, which is says it the world’s first fully 3D-printed carbon fiber downhill mountain bike. Why? Because they can. And to highlight the possibilities of Revel’s FusionFiber material. While the Rodeo is not currently for sale, it is a very real bike.

The Fine Print: Revel Rodeo

While the Rodeo is a functional bike, Revel will not be offering it for sale any time soon. Instead, the multi-year project is intended to prove what is possible with the rapidly-developing world of 3D printing. For Revel, the Rodeo is a chance to show the potential of its FusionFiber material. FusionFiber is a recyclable and environmentally responsible form of carbon fibre developed by CSS Composites and adapted to use in mountain bike wheels by Revel. It first found use in Revel’s RW30 composite wheels. Now Revel’s looking to see what’s possible.

Enter the printers. Revel worked with Arevo Inc., a brand already working in the additive manufacturing of bicycles, to see what is possible using FusionFiber for a full-suspension mountain bike.

Another World-first

The project is the work of Adam Miller (Revel Bikes), Chris Canfield 9CBF suspension inventor) and Jordan Haffener (Revel Bikes Senior Engineer). The trio spent years working with Arevo to design the Rodeo as well as the process of printing the bike. While there are 3D-printed parts and bikes out in the world already, the Rodeo is the first to apply the process to a full-suspension carbon fibre mountain bike.

There are a few reasons why Revel wanted to start with a downhill bike. Downhill is, generally, the most demanding bike to create from both design and usage perspectives. They are complex bikes to engineer. Out in the world, they’re ridden at the limits of what’s possible on two wheels. So if Revel could successfully work out the 3D printing process for a bike like the Rodeo, the trio figures, they would be on solid ground if they decided to use the process for future production bikes with simpler designs and demands.

What does Revel say about its 3D-printed mountain bike?

The Rodeo is just a concept for now. Still, it serves as an example of conviction, innovation, and what is possible with current technology and what could be a reality in the future. It’s hard not to get excited about the prospect of a 3D-printed carbon bike made here in the United States, and the ramifications could mean incredibly improved prototyping and development processes for bike brands, safer conditions in production facilities, significant environmental benefits, and greater customization for the rider at better costs.

Revel believes that this method of frame production could be the future for carbon bicycle manufacturing, and the Rodeo is proof that this is a real possibility that could become more of a reality for practical, reasonable-cost full suspension mountain bikes with continued technological advancements. A 3D-printed carbon mountain bike is doable, and with further innovation, there is even the potential for this thermoplastic composite material to be fully recyclable.

– Revel Bikes

Where to from here? The barn doors are now open…

Revel readily admits that the Rodeo, and 3D printing, are not quite ready for mass production. In its current state, Revel says, 3D printing is too time-consuming. The process is also prohibitively expensive.

But the Rodeo does open up a whole new range of possibilities for future mountain bike production. Revel may not be bringing the Rodeo to market anytime soon. But just creating this 3D bike opens the barn doors, so to speak. Now that the Rodeo, and this proof of the possibility of 3D printing complex frames are out in the world, there’s no closing those doors.

The exciting part will be seeing what comes next. Will Revel (or someone else) be able to take this technology to shake up the mountain bike design and production processes? It could just be a matter of time. Semi-custom or made-to-order bikes could replace set size runs. On-demand frame printing could open up big opportunities for smaller brands that don’t want to wait for a production run to be molded, manufactured and shipped from overseas. Or it could just speed up the time for smaller, more flexible brands to go from design to production.

Revel Rodeo

Check out the Revel Rodeo now.