Fillippo Ganna to ride a 3D-printed Pinarello Bolide F HR for his hour-record attempt

New frame uses new shapes and features for increased stiffness

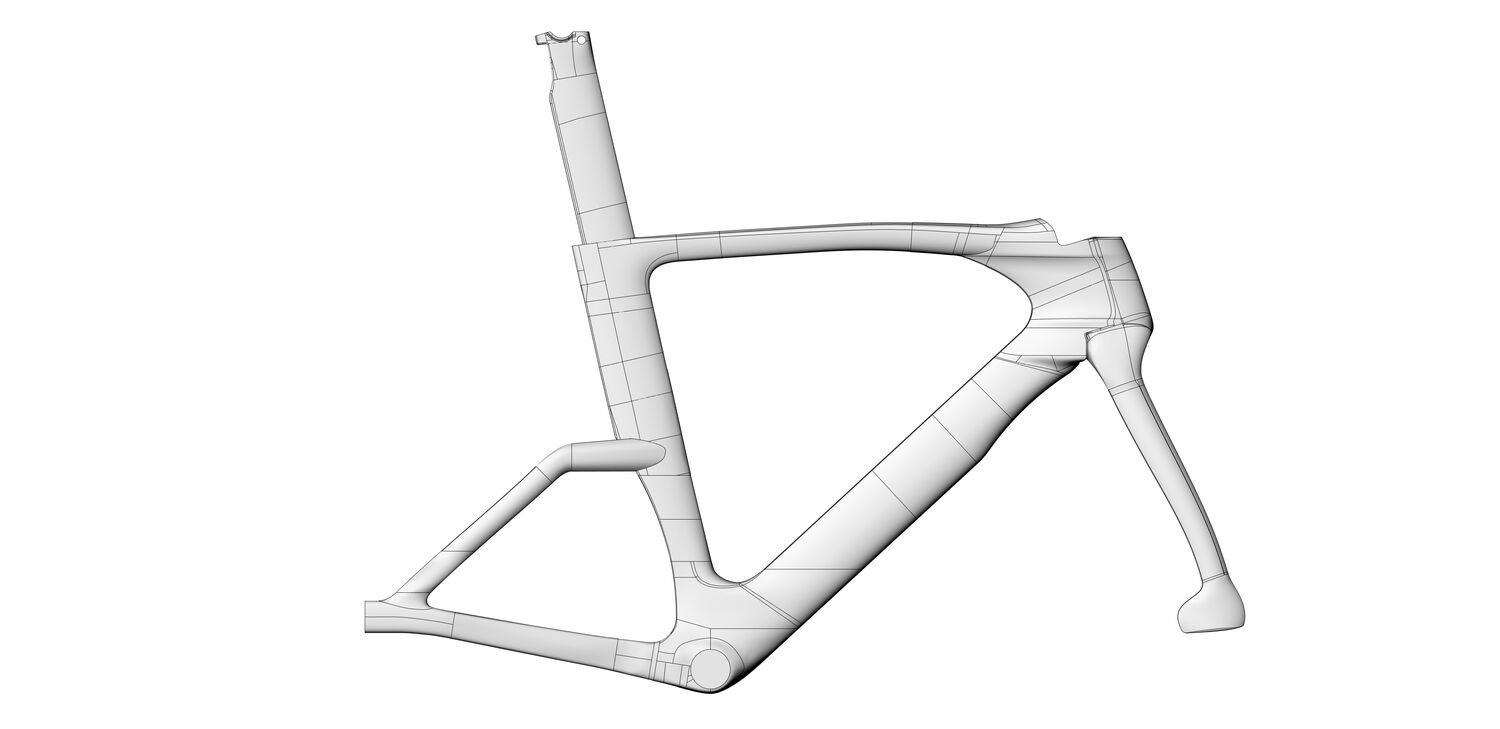

On Monday, Pinarello unveiled the brand-new Bolide F HR 3D, which Filippo Ganna will ride for his upcoming UCI hour-record attempt on Saturday in Switzerland.

Getting the bike to maximize aerodynamic performance and power transmission was of course, extremely important. Pinarello’s Bolide F HR 3D was designed around the rider, conforming to Ganna’s unique position to maximize both his comfort and overall aero performance. The Italian bike brand said that “comfort is often underrated, but when it comes to an UCI Hour Record timed by Tissot attempt it is absolutely crucial because it allows the athlete to go faster for longer.”

Getting the bike to maximize aerodynamic performance and power transmission was of course, extremely important. Pinarello’s Bolide F HR 3D was designed around the rider, conforming to Ganna’s unique position to maximize both his comfort and overall aero performance. The Italian bike brand said that “comfort is often underrated, but when it comes to an UCI Hour Record timed by Tissot attempt it is absolutely crucial because it allows the athlete to go faster for longer.”

The Italian bike brand also aimed to make the frame as efficient as possible. The importance of stiffness is also often underestimated for track bikes, according to Pinarello, but any flex under power causes the wheels to scrub, losing the athlete crucial centimeters every time a rider pushes the pedals.

With that in mind, new bike needed to blend strength and stiffness with aero gains, with a production method that would allow for perfect sizing.

“3D printing allowed us to introduce new shapes and features that are impossible to replicate with existing carbon fibre techniques. With this new method we have created a unique aerodynamic shape and reached an incredible level of stiffness,” Federico Sbrissa, Pinarello’s chief marketing officer said. “ Moreover, it made it possible to add internal reinforcement, create a totally new shape of head tube and importantly, it also drastically cut development time because we were no longer held back by the traditional time constraints of mould production for a carbon fibre frame.”

Sbrissa said that the project also marks the beginning of a new manufacturing era.

“This is such a unique project; we believe it’s the beginning of a new manufacturing era. The next step will be to make it more affordable by finding ways to scan riders with more affordable equipment and automatically design each unique bike. From a world champion, to every World Tour rider, and eventually to each and every cyclist out there,” he said.