The basic guide to thru axles

The frustratingly non-standardized wheel-holding component

From mountain to road bikes, disc brakes are quickly becoming the norm these days and with them comes the thru axle. Thru axles allow for easier and more consistant alignment, which is important for disc brakes which need to be properly aligned in a narrow calliper. If you’ve looked into new wheels or if you’ve even thought about connecting your thru axle bike with a trainer or a trailer you’ll know that the simple cylindrical component can cause some major headaches. But don’t worry, once you figure out what you need it’s (mostly) smooth sailing from there. Here is the basic guide to thru axles.

Why thru axles?

Originally designed for downhill bikes, thru axles are rapidly taking the place of the classic quick release skewers. They go in through one side of the fork/rear drop out, through the hub and screw into the other side of the fork/drop out (hence the name thru, or through, axle). While a quick release skewer uses compression to hold the wheel in place, a thru axle will uses a thicker rod threaded into the frame to hold the wheel in place. Thru axles provide a stiffer ride. Even if it somehow comes loose, your wheel won’t detach the way it could with a quick release skewer and vertical dropouts.

Why are there different sizes?

As with many things in the cycling industry, thru axles are not standardized. Your thru axle standard will depend on your bike’s manufacturer and your bike’s intended use.

How can I find my thru axle information?

Before you do anything else, do a quick google of your bike’s specs (make sure to specify the year). If you’re looking for your rear thru axle size to buy an adaptor for an indoor trainer you’ll want the ‘frame’ axle information, not the ‘fork’. It’ll look something like: 12×142 (width x hub spacing) sometimes written as 142×12, a popular road bike size.

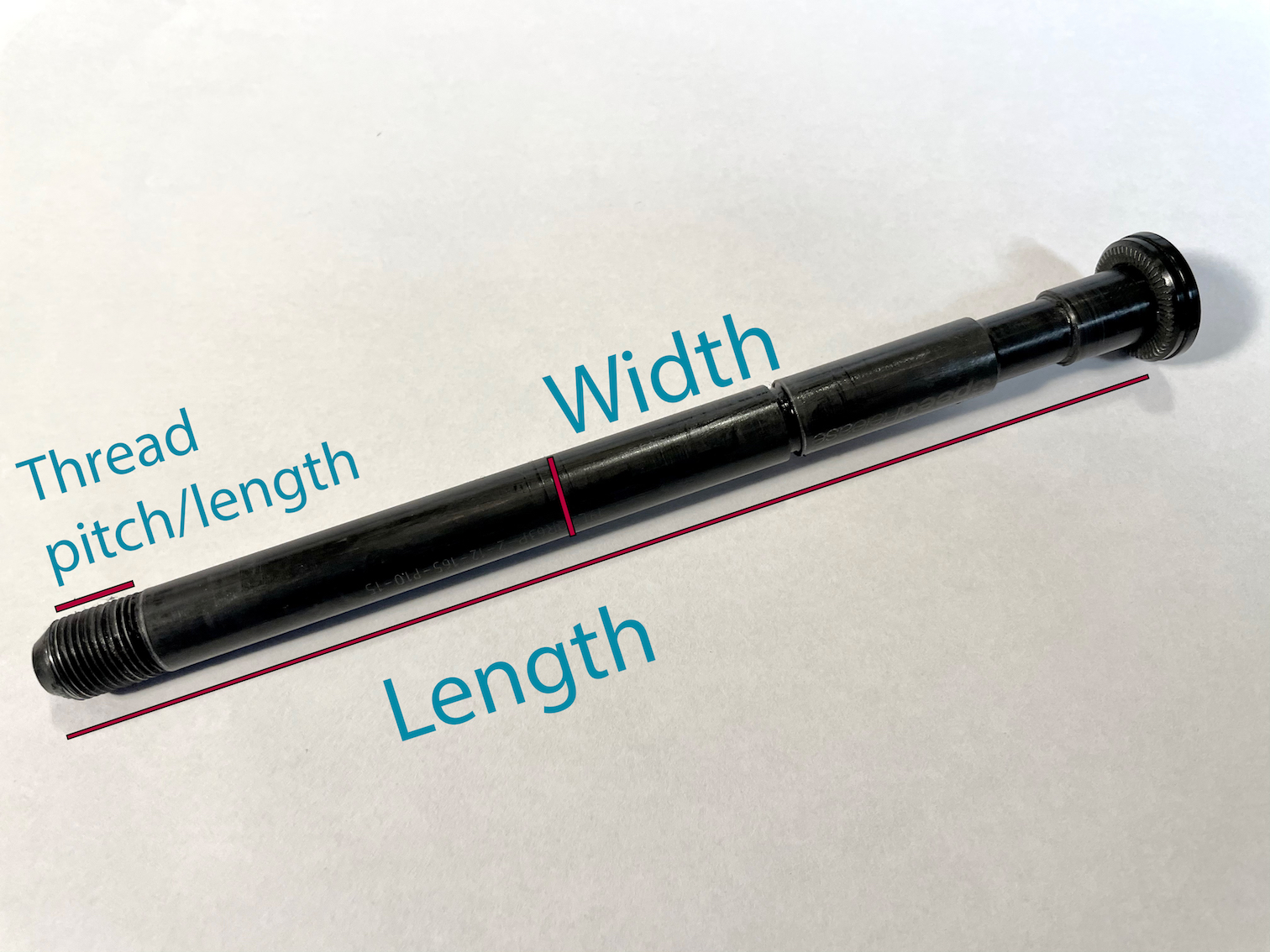

That information is good, but it’s not all that we need. Thru axles vary in length, width, seat type (is the end cone-shaped or flat?) and thread pitch/length. It screws directly into the frame or fork, so the thru axle has to have the right distance between threads (thread pitch) as the bike.

Robert Axle Project has a tool to figure out what size thru axle you need. Be warned, though it will point you towards the proper thru axle, it often won’t give you all the information you need on your axle standard leaving you with no choice but to buy the company’s product. The company offers a sheet you can print to find your thread pitch and axle length.

In this example, the axle is 12mm wide and the hub spacing is 142mm so we still need the tread pitch, axle length and axle seat type. Some thru axles have the thread pitch printed on the side (marked as TP). Cameron Ward at Brockton Cyclery in Toronto recommends first pulling out the thru axle and checking for printed numbers. While you’re handling the axle, check to see if the end is cone-shaped or flat and measure the length from the base of the head to the end of the threads. If your axle has no writing on it, Ward says you have a few options. “Check the manufacturer’s technical information website,” he says. “Failing that, your local bike shop can help you figure out compatibility using measuring gages or by calling the manufacturer directly. We can help bridge a thru axle compatibility minefield.”

Once you have all the information on your thru axle sizing you’ll be ready to attach your bike to anything (or anything to your bike), replace components and get riding.