A wheelset custom-built specifically for you and your bike can give you a huge performance boost. What’s key is making sure you get what you need and working with the right wheelbuilder. Also important is selecting the hubs, rims and spokes you for the wheelset. “The question is always what’s important to you,” advises Mackenzie Ogilvie, head wheelbuilder and service manager at Urbane Wheels. “Usually the ideas we start with are very different than the wheelset we end up with.”

To start, you should give the wheelbuilder as much information about yourself and your bike as possible. While you may have preferences, keep in mind a wheelbuilder like Ogilvie has a lot of experience and can make recommendations based off of the information you have provided. The more the wheelbuilder knows about your physique, your bike, your riding style, the wheels’ intended use and your experience working on and maintaining your equipment, the better.

Whether for road, cyclocross, gravel or mountain bike—there is lots to consider when starting a custom wheel project. What you want will be balanced with what suits your needs best. Choosing the right rims, hubs, spokes and lacing pattern is where the process starts.

Rim selection

The wheel-building process starts with a discussion on the intended use of the wheels. Do you need strong hoops? Light wheel? Is aerodynamics a priority? Answering these questions will help narrow down the choice of rim. Urbane has a wide selection for you to choose from. Staff will do their best to accommodate any special requests.

There’s a lot to consider choosing a rim. Its depth will affect the finished wheel’s aerodynamics while the material it’s made from will influence its ride quality, stiffness and weight. Lightweight and deep-section aero wheels are usually built from carbon fibre while sturdier adventure or training wheels are alloy.

While carbon fibre is sexy, there’s a wide range of quality alloy options to consider as well. “It’s sort of the golden age of alloy in terms of rims,” Ogilvie says. A wider inner-rim profile can make a wheelset better suited for gravel and adventure tires if your frame has the clearance.

Most road wheels are 700c while mountain bikes run 27.5” and 29”. If you have a gravel bike that can fit 650b (27.5”) mountain bike rims, you have even more options to choose from.

The braking system on your bike will also affect the selection. Carbon rim-brake tracks are probably not the best choice if you plan to ride in the wet or take extended off-road adventures. The rim will dictate the spoke count, so if you need something very sturdy to support your weight or for rough adventure rides, a lightweight carbon rim that only uses a low spoke count is probably not right for you. Another important consideration is tire choice. If you’re competitive, you might want race-day hoops that run tubular tires. Or, you might want the puncture-management abilities of tubeless-tire-compatible rim. Finally, you might want clinchers for convenience and ease of installation.

Hubs and bearings

Firstly, hub choice is dictated by your brakes: rim or disc. If you run discs, make sure your rotors will fit the hub you choose. Your options will then be narrowed down by the frame’s axle type—thru axle or quick release —and the space between the dropouts. Consider how sturdy you want the wheel to be when considering which hubs to use. Talk to the builder about weight—both yours and that of bikepacking gear you might use. Also, the surfaces you envision riding on will help determine the spoke count required to build the desired wheelset.

Urbane always recommends building wheels with hubs that are easy to service. “The bearings are all readily available. If a hub is too difficult to service or it requires specialized service, then I am less likely to recommend it,” Ogilvie said.

Smooth bearings are always desirable but the smoothest components will set you back a bit more. The bearing type also affects how easy the hub is to service. If you ride in messy conditions, you want to make sure your hubs are well-sealed. If keeping grams at bay is a priority, look to hubs with carbon or lightweight alloy bodies.

Many hubs use a ratchet-and-pawl mechanism to engage the freehub, on which the cassette sits. Ratchets with fewer and bigger teeth are good for dealing with a lot of torque, while more numerous and smaller teeth usually engage faster. There are also other freehub engagement systems to consider. Like all components of a wheel, your budget will have an affect on which hubs are right for your new wheelset.

Spokes and patterns

The final major component of the wheelset is the spokes. Spokes come in many different shapes, colours and sizes. Straight-gauge spokes, butted, double-butted and aero spokes all have different purposes. Your hub will dictate whether you need j-bend spokes or straight-pull ones. The hub and rim you choose will also set which patterns are possible. Your weight and riding style affect whether certain patterns can and cannot be used. Do listen to the wheelbuilder’s suggestions.

Urbane Wheels has an extensive, organized drawer system stocked full of different types of spokes. Ogilvie and his wheelbuilder’s know the limits of the wheelsets they are working on so listening to their advice when it comes to spoke pattern and selection is a good idea.

“I have had people say straight up they don’t want too many spokes because they don’t like how it looks,” Ogilvie explained. “They will have to spend a lot more time and money servicing the wheels because they won’t stay true.”

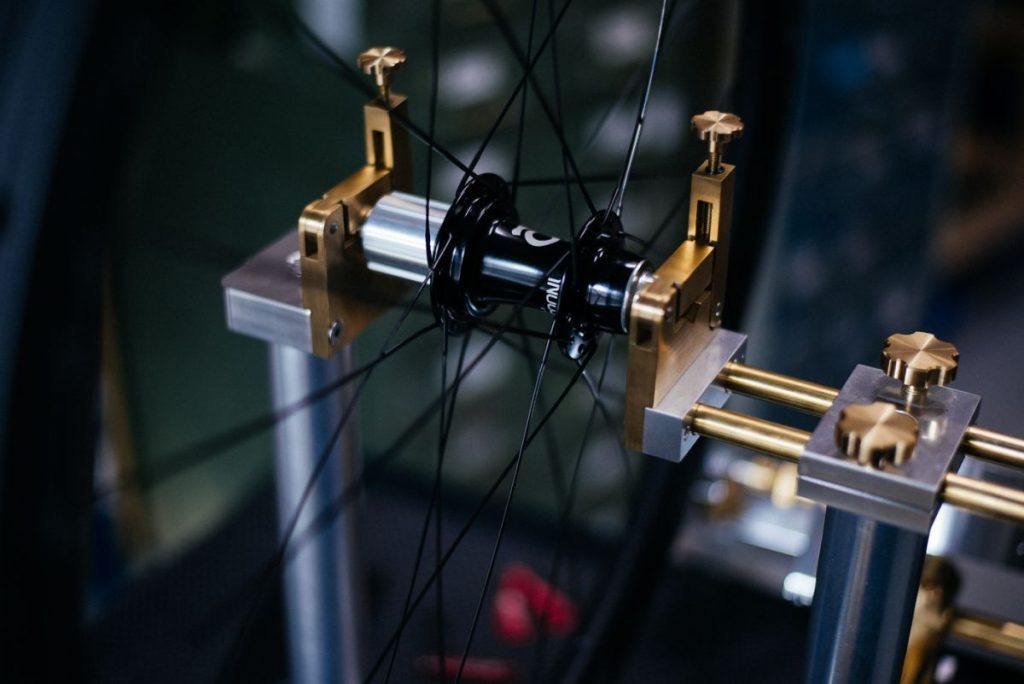

The wheelbuilder will then measure the length from the hub’s flange holes to the spoke holes on the rim. The length needs to be exact and the spokes are then cut to length with a special tool.

More spokes mean the load is spread more evenly and results in a stronger wheel. Of course the higher spoke count adds weight. Three-, two- and one-cross spoke patterns can be used to add variable levels of stiffness and strength, while radial patterns may look awesome but are only suitable for a select few builds.

While spokes can be easily overlooked, they are what hold your wheels together. At the rear, the spokes are responsible for transferring the power from the hub to the rim to move you down the road and maybe ahead of your fellow riders. If the spokes are wrong, your wheel won’t stay true and you might get broken spokes.

The wheelset you want and need

With the components selected, it’s up to the wheelbuilder to put it together. At Urbane, Ogilvie inspects all the wheelsets that leave the wheel-building room. “With anything custom, you can’t test it out. I don’t always meet the people in person and have a chance to talk. They are trusting that I will do the right thing,” Ogilvie says about the importance of a good wheelbuilder.

To find out more about getting a new wheelset, read all about why you need a custom handbuilt wheelset.