First Look: Shimano’s Dura Ace R9100

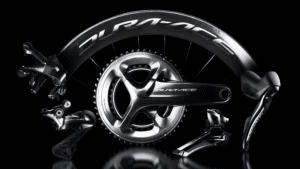

Shimano groupsets have a strong reputation for reliability and consistency, so too for Shimano the company. Every four years or so, one can count on Shimano to update its groups. As it was late 2012 that Dura Ace last received an update, as a 2013 product, we are due. The watch word for this redesign is system engineering, taking a system approach to designing the groupset, and every component has been reconsidered, refined or otherwise overhauled. The highlights are an integrated powermeter, all new Dura Ace level disc brakes, more integration between components for cleaner aerodynamics and looks, and more consistent ergonomics across electronic, mechanical and hydraulic versions. The new groupset also borrows much from the MTB side, with “Shadow” Direct mount rear derailleurs, and Syncro Shift.

New Integrated Powermeter

The new crankset retains the familiar 4-arm design, but is now asymmetrical and beefier than previous. The biggest news is the addition of an integrated powermeter. Shimano has been at work on a powermeter for ten years, and with this latest release they finally feel they have a worthy system, and it shows. The entire sysem is hidden within the crank arms, the only difference is a very small transmitter attached to the drive side crank arm, which also houses LED for diagnostics, and a magnetic charging port for the power meter battery. Speaking on the new powermeter, Shimano’s Road Product Manager David Lawrence, “we’ve been working on this for quite a few years, it’s based off the technology from our bike fitting system, which has the torque sensors in there as well.”

Two new wheel options

Two new wheel ranges are introduced at the 40mm and 60mm rim depth, in full carbon tubular, full carbon tubeless compatible clinchers for disc brake systems, and aluminum with carbon laminate clincher wheels for rim brakes. The new tubulars are on trend with 28mm wide outer rim. In the product presentation, Shimano’s European manager claims, “the new 40mm and 60mm wheels saves 2w and 16w respectively (at 7.5 degree yaw with 25mm tires) when compared to the C50, the previous all rounder.”

Unfortunately the new wide rim shapes are limited to the tubulars, the clinchers, whether rim or disc brake versions remain at 24mm width, wider than traditional designs, but not as wide as some of the most recent wheels. The new wheels will replace the C50 and C75 wheel depths.

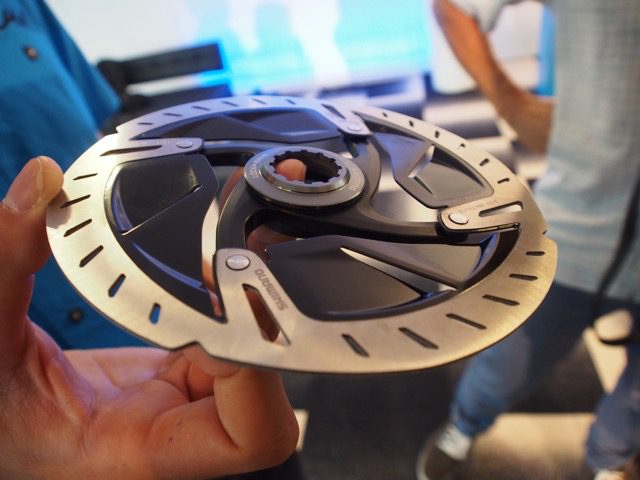

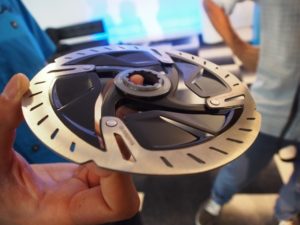

New Disc brakes system

When Shimano launched their Road Hydraulic disc group, the R785, it was conspicuously labeled a non-series group, roughly equating to Ultegra level. Leading to speculations that there will be a Dura Ace level group that will debut down the line. The rumors are confirmed with this latest update, with hydraulic disc for both mechanical and Di2 set ups. The new top end disc brake features an all-new rotor, with the aluminum alloy sandwich construction extending all the way to the centre mount for increase heat dissipation.

The flat mount calipers are reduced in size, with a triangular shape, to fit more tightly into rear triangles and fork, giving a sleeker look more inline with traditional road setups. Mechanical calipers too are now smaller than before, though the differences are less obvious to the eye. The new brakes now also accommodate 28c tires officially, though some 30c might fit depending on frame and tire combinations. To make up for the loss of stiffness from increased clearance and reduced size, the new calipers features a small brake booster that fits between the arms.

Syncro shift for road

First introduced on the XTR and then XT mountain groupset, Syncro shift are now available on the road. Arguably the most exciting feature of the XTR Di2 groupset, “Synchronized Shift” is a somewhat complicated concept to explain, but rather simple to use in riding. Similar to standard Di2, one can control the front derailleur with the left shifter, and the rear derailleur with the right shifter. Or vice versa, or upper shift lever for front shifts, and lower shift levers for rear shifts. Or any variation you desire, as are programmable multi-shifts, since the new Dura Ace Di2 continues to use the same programmable e-tube wiring and software. So far, pretty standard.

However with R9150 Di2, Shimano introduces the idea of “Synchronized Shifts”, or the ability to shift sequentially to the road as well. Let’s say you are climbing up a hill with a mechanical setup, and you’ve shifted to your biggest cog, whilst in the big ring, so now cross chaining. In order to go to a lower gear and continue up, you would need to shift to the smaller ring in the front, but that suddenly puts you in a much lower gear, causing you to wildly hamster wheel your legs all of sudden. Or worse, you were too cross eye to realized you had run out of cogs in the back, and depress the right shifter only to discover no easier gear to go, thus stalling out or even falling over.

The logical thing to do would’ve been to shift down two cogs in the back before shifting to the small ring in front, since that is the next sequence in terms of gearing, but that is not always possible, especially when one is on the limit and not thinking clearly.

With the new synchronized mode, that is exactly what happens. The electronic brain of the shifters will make the rear shift first, followed nearly simultaneously by the front shift. This is made possible by the powerful servo motors used for the electronically powered derailleurs, which is able to auto trim, as well as shift faster while under much greater load than spring driven mechanical setups.

Like XTR, the new Dura Ace Di2 can be programed with two customizable “Synchroized Shift” modes, full Syncro which shifts front and rear, semi Syncro which only adjusts the rear depending on the action you choose on the front drailleur, as well as a traditional manual shift mode that is accessible at anytime and will over ride the preprogramed shifts.

There is also a new miniaturized junction A, which can be hidden in the handlebar end, or in frames with built in compartments. Which gives the same LED, adjustments, and charging functions as the previous under stem version, whilst giving a clean, unclutter appearance to the bike.

Mechanical system not forgotten

With all the attention on Di2 and hydraulic disc brakes, one would be forgiven for thinking that mechanical systems are obsolete, but Shimano certainly does not feel that way. Tim Skeritt, European Product manager commented that, “We have two separate team for mechanical and di2 shifting, and the two really drive and challenge each other, we’ve gotten better results from this competition than I think we otherwise could.”

The new mechanical system receives the same “Shadow” direct mount rear derailleur as the new Di2 rear derailleur, which provides a stiffer platform and better clearance, allowing the use of the wide range 11-30 cassette. The front derailleur received the more radical update, with both the di2 and mechanical FD dramatically smaller than before. Gone are the long arm mechanical front derailleur, instead the new FD utilizes a toggle mechanism, which is smaller and less sensitive, yet as effective as long arm, and provides more clearance for compact frame and wider tires. One feature that mechanics will love, is the new FD also comes equipped with an allen bolt that adjusts cable tension, replacing the need for barrel adjuster.

Ergonomic was also a big focus for the updated Di2, with the goal of giving consistent feel across the different hoods. In fact when asked, Dave Lawrence said “getting the brake lever shape is probably the greatest engineering accomplishment, to where you can go back and forth between a standard rim brake di2 lever and a hydraulic di2 lever, and not feel a difference.” The new Di2 hoods for rim and disc brakes are extremely similar in feel, virtually indistinguishable.

While the new shift hoods are similar in design to the current 9000 series hoods, although they feature a textured rubber surface, and feel slightly smaller in hand, closer to the Di2 hoods.

Waiting for the road test

Limited availability for North America is slated for this fall, with the mechanical Dura Ace 9100 rim brake group available as early as September, follow by Di2 rim brake group in January, and the hydraulic disc groups (both mechanical and di2) in March, finally with a TT disc group set next summer. Canadian pricing is still to be announced. We will be taking a first ride road test tomorrow, stay tuned for our first ride impressions.