by Mark Cohen

In Ravenshout, Belgium, in an ordinary industrial complex like the others nearby, Bioracer the country’s most prominent kit designer is busy filling orders for the 500,000 athletes who will race or ride in their kit in 2016. The company’s offices are a maze of innovation. In one, kits are envisioned by an in house design team (they will do 3,500 designs in a year); next door, a chamois machine mimics riding Paris Roubaix to stress test fabric durability.

Bioracer is betting heavily on technology to create betterfitting kits that translate to more watts for end users. But how is this Belgian company located about 20 minutes from Ridley Bikes and the just built Flanders Bike Valley wind tunnel project quietly becoming the cycling kit of choice for European club riders and pros? Alongside international media from California, China, Germany and elsewhere, Canadian Cycling Magazine took a look inside the company’s head office to find out.

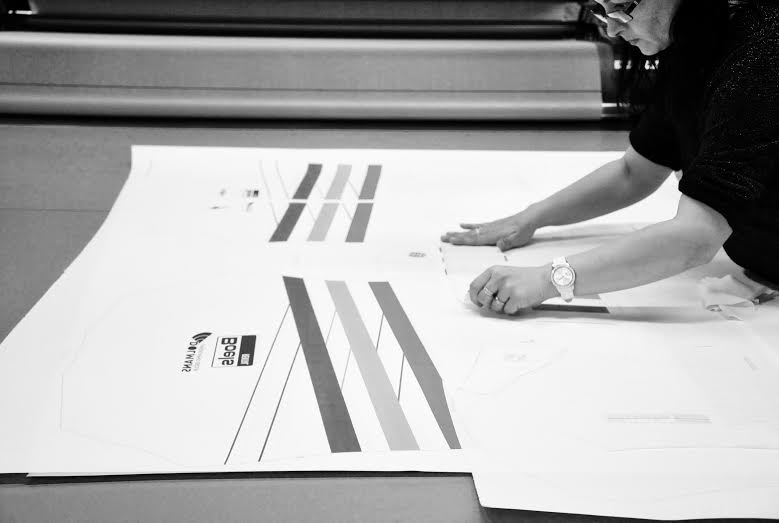

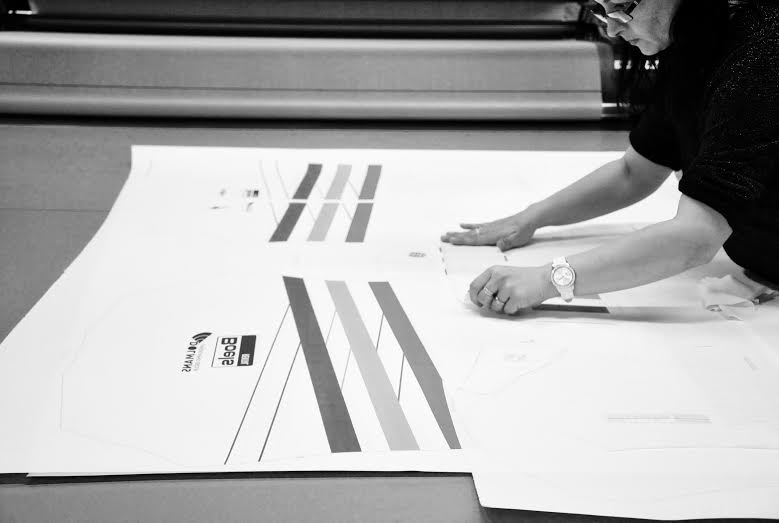

Ever wonder how designs make it onto different kit? Seen here: one of Bioracer’s employees sublimating designs onto white fabric panels that will eventually become a jersey.

A river of chamois on display inside Bioracer’s factory and in the background, a machine that tests them all for durability and comfort by simulating some of cycling’s tougher parcours like Paris-Roubaix.

A Bioracer company spokesperson explains the company’s fabric elasticity machine testing.

Bioracer kits are created by the company’s in-house design team.

Because of the micro drops of oil used for wind tunnel testing, riders will very rarely sit on bikes for aerodynamic tests. Instead, rider molds are made like the one seen here of Tony Martin wearing Bioracer kit inside the just-built Flanders Bike Valley wind tunnel.

Every year, Belgium-based Bioracer designers create 3,500 kit layouts for club riders and pros. Seen here: just some of the team’s handiwork on display inside the company’s design studio.

Bioracer athletes in various states of duress: from time trials to road to group rides, the company designs kits for all rider types. Also below, one of the company’s digital printers used to create designs which are then sublimated onto fabrics. The company has been using vegetable dyes in their kit for several years.

Many steps in the manufacturing process are still done by hand. Seen here: Jersey panels are sewn together inside Bioracer’s Speedcenter HQ.